Wireless Automated Straddle Control System

.JPG)

As trade becomes more liberalized, tariffs drop and barriers to entry fall, transport costs have become one of the key obstructions to market access and increases in per capita income. And one of the fundamental determinants of transport costs is port efficiency.

Patrick terminals, once described as slow, inefficient and unproductive, are exceeding the Australian government crane rate benchmark of 25 moves per hour, figures on par with world's best practice. Not content with being with the best, Patrick sought to lead the rest in the development of technologically advanced management of containers within terminals.

Initially, Patrick Corporation, through its technology arm Patrick Technology & Systems (PTS), developed ground-breaking IT and communications systems allowing seamless integration of its extensive freight management, logistics and operations.

Continuing on this approach of innovation and technology, Patrick proposed the use of an automated container handling system. This lead to PTS, in conjunction with the University of Sydney and Kalmar Industries of Finland, to pioneer the world’s first fully automated straddle carrier known as the Autostrad™.

With first class engineering, original thinking and Patrick’s commitment to innovation, the Autostrad has become the flagship of future port efficiency. The system uses free-ranging machines that can roam without constraint in a terminal with only the most minor infrastructure change. Comparative systems in the world rely on expensive, special in-ground cables, or transponders on specialist vehicles to make automation possible. The Autostrad concept allows existing manual machines and ports to be minimally retrofitted with automation gear yet have maximum flexibility in use.

The key obstacle to automation is to reliably and consistently know where the vehicle is at all times. This is difficult since no one sensor is perfect. Hence the automated machines incorporate a great deal of systems redundancy to achieve its goal of safe, reliable and precise automation.

Operationally, the Autostrad transports boxes from the quay crane to the yard, and from the yard to road vehicles. Throughout this process the environment is consistent except for the variation in truck beds, slopes and types. To combat this variation, when the AutoStrad is required to place a box on a truck, it enters “teleoperation” (“teleop”) mode.

In this mode, the straddle is controlled remotely via an operator on the ground. The operator simply completes the last part of the unloading process: the accurate placement or pick of a container on or off a truck bed.

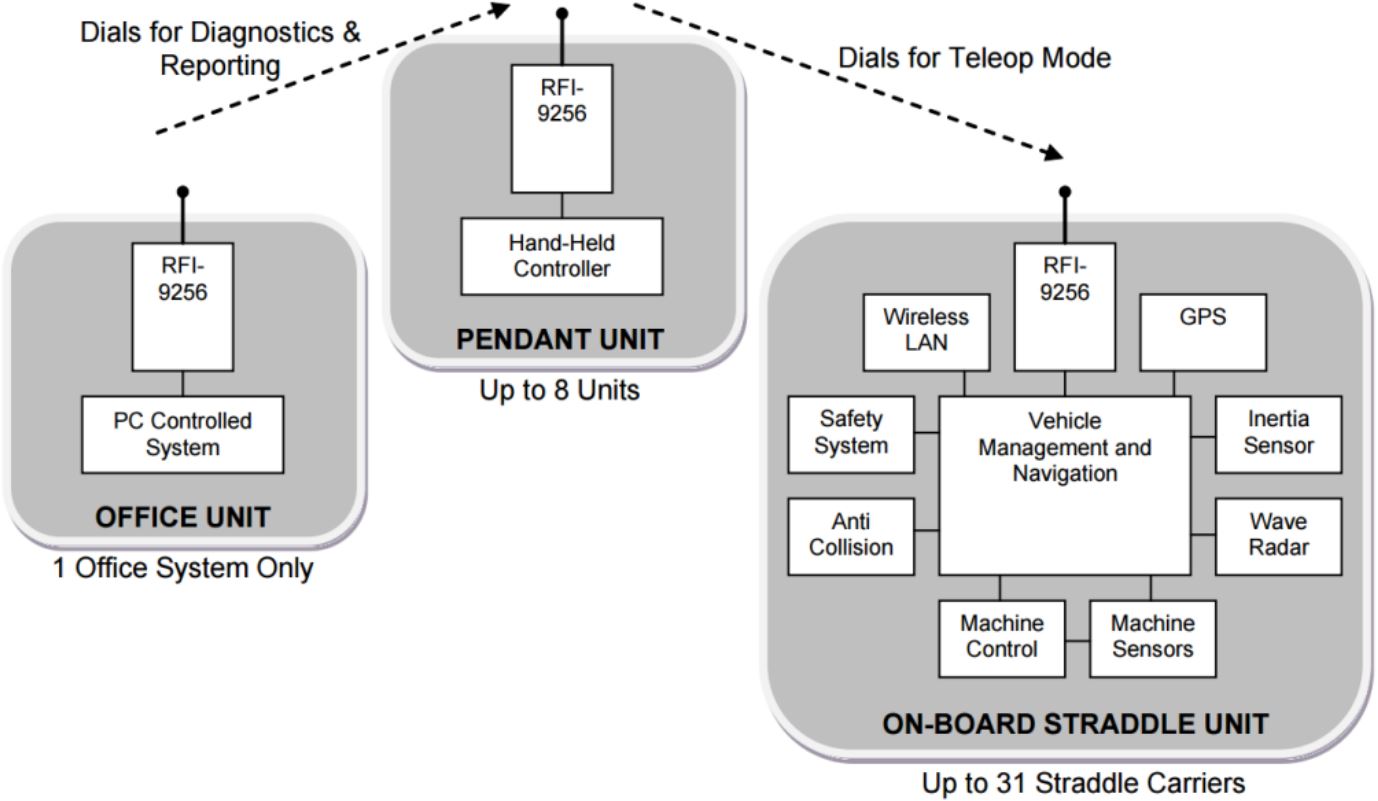

Obviously, in this process reliable communication is critical. Furthermore, the system needed to minimize power use, be physically robust as well as have excellent transmission properties. After an exhaustive search, PTS settled on the RFI-9256 modem as the core of the teleop system on the AutoStrad. The unit met all the requirements as well as being reasonably priced and “developer-friendly”.

Each pendant and each straddle has an RFI-9256 radio modem built into it, working in a master/slave configuration. Pendants connect to straddles via a Hayes compatible protocol, box moves are completed and then the AutoStrad completes the rest of its move autonomously. And after 1000’s of hours of operational use without failure, the decision to use the RFI-9256 appears to be vindicated.

After their initial introduction into a trial berth at Patrick’s Brisbane terminal, Australia’s third largest and fastest-growing port, the Autostrad has exceeded all expectations. Each of the vessels the Autostrads serviced have easily departed on schedule. The cranes are consistently exceeding 28 moves per hour, and at times have achieved as many as 40 moves per hour. Patrick has now committed to the full automation of its Brisbane terminal including 15 Autostrads and 3 Portainers due to be completed by the end of 2005. This is to be followed by the redevelopment of Port Botany in Sydney with plans to become a revolutionary multimodal facility complete with Autostrads, automated rail mounted gantries, rail and road access by 2008.

The success of the project has come about through Patrick’s commitment to innovation, engineering excellence and technology. This coupled with a drive to lead where others follow will continue to see Patrick remain at the forefront of the drive to faster, more efficient and more productive ports.

Contact us for further information.